Fabreeka-TIM® Structural Thermal Breaks

Energy Savings and Thermal Breaks

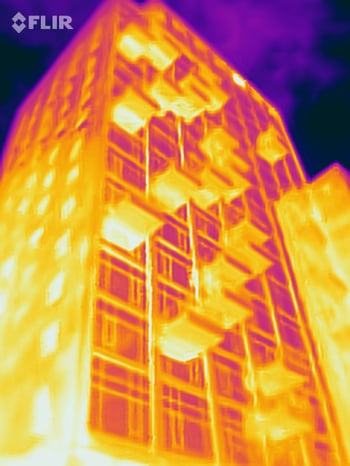

Reducing energy usage in buildings has been a focus within the construction industry for years. Efforts to reduce energy use typically focus on windows and doors, mechanical systems and lighting. However, thermal bridging in the structural frame of the building often gets overlooked:

-

In structural steel buildings, thermal bridging occurs when a conductive material acts as a conduit or “bridge” for heat transfer.

-

Heat finds the path of least resistance in cold and warm climates, transferring to the colder side whether that’s indoors or outdoors.

-

Up to 1/3 of a building’s energy can be lost due to thermal bridging.

-

New research and software allow us to better analyze and understand thermal bridging to develop solutions.

Thermal Bridging Solutions with Fabreeka-TIM®

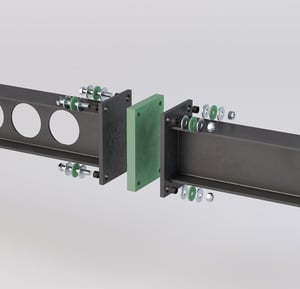

To greatly reduce the heat flow through a steel beam, install a structurally sound, Fabreeka-TIM® thermal break between the steel flanges.

Fabreeka-TIM® structural thermal breaks in a moment connection and provides many benefits:

- Increases energy savings by the introduction of a properly designed Fabreeka-TIM® thermal break, including Fabreeka-TIM® washers and Fabreeka® bushings

- Helps achieve LEED certification and meet various energy code criteria

- Minimizes condensation concerns

- Improves occupancy comfort

Request Info

Following are some of the benefits of using Fabreeka-TIM® structural thermal breaks in a moment connection:

- Consumers and building owners will benefit from increased energy savings by the introduction of a properly designed Fabreeka-TIM® thermal break, including Fabreeka-TIM® washers and Fabreeka® bushings to completely break the bridging path

- Used to achieve LEED certification and meet various energy code criteria

- Minimize condensation concerns

- Improve occupancy comfort

Fabreeka has resources to assist you when designing and specifying Fabreeka-TIM® structural thermal breaks:

- Fabreeka-TIM® is ICC ES Listed in both the US and Canada

- We have created a CSI 3-part Guide Specification for specifying Fabreeka-TIM®

- Available brochures Fabreeka-TIM structural thermal break for moment connections and Fabreeka-TIM RF light load structural break

Fabreeka-TIM® material is supplied in sheets or cut to size per customer drawings and/or specifications and is available in thicknesses of 1/4” (6.4mm), 1/2” (12.7mm), 3/4” (19.1mm), 1” (25.4mm) and 2” (50.8mm). Precision water jet cutting is available for holes and special joints.

Fabreeka-TIM® material is also supplied as thermal break washers for the bolted connections between external and internal steelwork. For optimal thermal break, the area around the fastener hardware should be taken into consideration. In addition to the Fabreeka-TIM® plate, we recommend Fabreeka-TIM® thermal break washers and bushings made from Fabreeka® material.

Fabreeka has several thermal bridging solutions depending on your application, and has engineers available to answer your questions. Please fill out the form above to request information, or ask for engineering assistance.